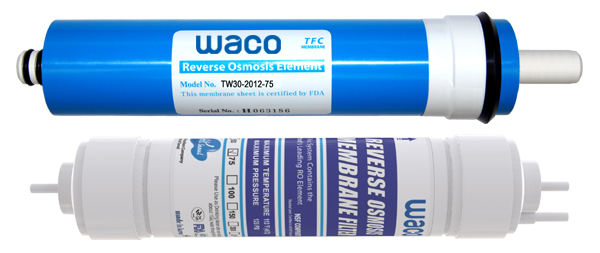

RO Membrane Filter

R.O membrane elements for home drinking water are the industry’s most reliable. Advanced membrane technology and automated fabrication allow these elements to deliver consistent performance that equipment suppliers, water treatment dealers and residential customers can rely on. WACO Corp R/O elements are shipped dry for convenient handling and long shelf-life. These are NSF/ANSI Standard 58listed.

|

RO MEMBRANE PRODUCTION FACILITY

Maintenance Room - Low temperature & Humidity

|

Full Auto Mechanism

|

Filter test Mechanism

|

Reverse Osmosis Membrane Filter

|

Characteristics of RO Membrane

|

▶

▶

▶

|

R/O Membrane Filter eliminates all pollutants such as heavy metals, virus, bacteria and organic chemicals through stomata with the size of 0.0001 um, which is 1/1,000,000 of the thickness of human hair.

R/O Membrane separates organic chemicals better than inorganic chemicals and electrolytes better than non-electrolytes. R/O Membrane can eliminate not only the substances of particle nature bur also the substances of ionic nature, the particle size of which is very small.

R/O Membrane separates substances without changing the phase of the substances and is applicable to various fields as it has good physical and chemical durability.

|

Superior Rejection Rate of R/O Membrane (Rejection, %)

|

| Substances |

Rejection Rate (%) |

| IONS |

99+ |

| Nitrates |

95 |

| Organics |

95 |

| THM |

99+ |

| Silica |

98+ |

| Bacteria and Particles |

100% |

| Dissolved gases |

Unable to eliminate |

Reverse Osmosis Phenomena

|

|

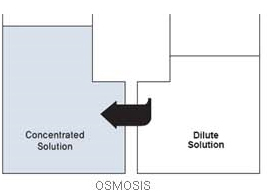

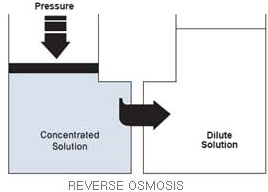

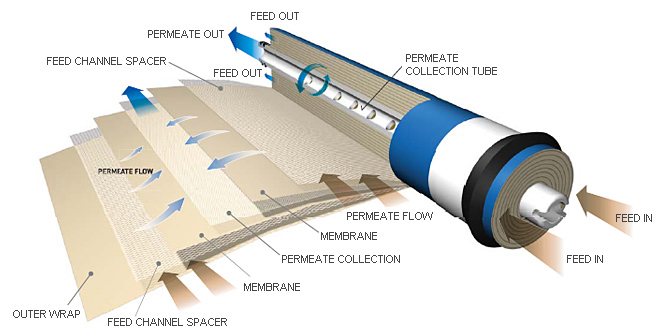

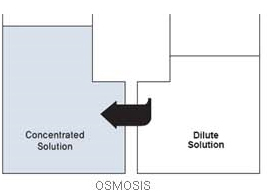

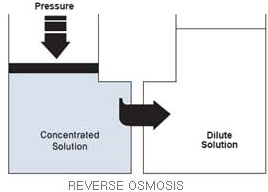

When solutions which have differences in concentration is separated by semi-permeable membrane, the water solution with low concentration moves toward high concentration side after lapse of certain time making difference in water level which is called osmosis phenomena The difference in water level generated at that time is called osmotic pressure while water solution with high concentration moves toward low concentration side if pressure that is higher than osmotic pressure is given to the solution with high concentration, which is called Reverse Osmosis phenomena.

|

Feedwater pressure affects both the water flux and salt rejection of RO membranes. Osmosis is the flow of water across a membrane from the dilute side toward the concentrated solution side.

Reverse osmosis technology involves application of pressure to the feedwater stream to overcome the natural osmotic pressure. Pressure in excess of the osmotic pressure is applied to the concentrated solution and the flow of water is reversed. A portion of the feedwater (concentrated solution) is forced through the membrane to emerge as purified product water of the dilute solution side (please see Figure1).

|

|

Figure 1. Overview of Osmosis / Reverse Osmosis

|

|

|

|

Water diffuses through a semipermeable membrane toward region of higher concentration to equalize solution strength. At equilibrium, the height difference between the concentrated and dilute sides corresponds to the osmotic pressure differential between the two sides.

|

Applied pressure in excess of osmotic pressure reverses water flow direction hence, the term “reverse osmosis”

|

As shown in Figure 1, reverse osmosis occurs when the natural osmotic flow between a dilute solution and a concentrated solution is reversed through application of feedwater pressure. If percentage recovery is increased (and feedwater pressure remains constant), the salts in the residual feed become more concentrated and the natural osmotic pressure will increase until it is as high as the applied feed pressure.

This can negate the driving effect of feed pressure slowing or halting the reverse osmosis process and causing permeate flux and salt rejection to decrease and even stop.

|

|

|

R.O Membrane 300GPD Filter

|

WACO Corp R.O Reverse Osmosis (R.O) membrane elements for home drinking water are the industry’s most reliable. Advanced membrane technology and automated fabrication allow these elements to deliver consistent performance that equipment suppliers, water treatment dealers and residential customers can rely on.

WACO Corp R.O elements are shipped dry for convenient handling and long self-life. These elements are SNF/ANSI standard 58 listed.

|

| WACO Corp R/O Membranes |

Home Drinking Water RO Elements

|

|

WACO Corp R/O reverse osmosis (RO) membrane elements for home drinking water are the industry’s most reliable, Advanced membrane technology and automated fabrication allow these elements to deliver consistent performance that equipment suppliers, water treatment dealers and residential customers can rely on. WACO Corp R/O elements are shipped dry for convenient handling and long shelf-life. These elements are NSF/ANSI Standard 58 listed.

WACO Corp R/O home drinking water elements are rated a 50 psi and will purify about 20% more water than competitive elements rate at 6 psi (please reference charts on page two for more information)

|

1.

2.

3.

|

The membrane element is supplied in dry condition to have more shelf life (12 month)

The life of elements is much stable and longer

The membrane is manufactured by full automatic machine to keep quality assurance.

|

| Product Name |

Permeate Flow Rate(GPD) |

Applied Pressure Psi (bar) |

Stabilized Salt Rejection (%) |

Minimum Salt Rejection (%) |

Remarks |

| 50 GPD MEMBRANE |

50GPD |

60 (4.1) |

98 |

96 |

Dry Type Elements |

| 75 GPD MEMBRANE |

75GPD |

60 (4.1) |

98 |

96 |

Dry Type Elements |

| 100 GPD MEMBRANE |

100GPD |

60 (4.1) |

98 |

96 |

Dry Type Elements |

| 150 GPD MEMBRANE |

150GPD |

80 (5.5) |

98 |

96 |

Dry Type Elements |

| 300 GPD MEMBRANE |

300GPD |

145 (10) |

98 |

96 |

Dry Type Elements |

1.

2.

3.

|

Permeate flow and salt rejection based on the following test conditions : 250ppm (NaCL) softened tap water, 77℉(25℃), 15% recovery and the specified applied pressure.

Permeate flows for individual elements may vary +/-20%.

For the purpose of improvement, specifications may be updated periodically.

|

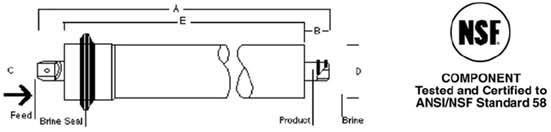

| Product Name |

A |

B |

C |

D |

E |

| 50 GPD MEMBRANE |

298 |

22 |

17 |

44.5 |

263 |

| 75 GPD MEMBRANE |

298 |

22 |

17 |

44.5 |

263 |

| 100 GPD MEMBRANE |

298 |

22 |

17 |

44.5 |

263 |

| 150 GPD MEMBRANE |

298 |

22 |

17 |

44.5 |

263 |

| 300 GPD MEMBRANE |

298 |

22 |

21.3 |

44.5 |

263 |

| Membrane Type |

Polyamide Thin-Film Composite |

| Maximum Operating Temperature |

113℉ (45℃) |

| Maximum Operating Pressure |

300psi(21bar) |

| Maximum Feed Flow Rate |

2.0 gpm(7.6lpm) |

| Ph Range, Continuous Operation |

3.0 ~ 10 |

| Maximum Feed silt Density Index |

‹ 5 |

| Free Chlorine Tolerance |

‹ 0.1ppm |

◎

◎

◎

◎

◎

◎

|

The First full tank of permeate should be discarded. Do not use this initial permeate for drinking water or food preparation.

Keep elements moist at all times after initial wetting.

If operation limits and guidelines given in this bulletin are not strictly followed, the limited warranty will be null and void.

To Prevent biological growth during prolonged system shutdowns, it is recommended that membrane elements be immersed in a preservative solution.

The membrane shows some resistance to short-term attack by chlorine ( Hypochlorite) Continuous exposure, However, may damage the membrane and should be avoided.

The Customer is fully responsible for the effects of incompatible chemicals and lubricants on elements. Their use will void the element limited warranty.

|

TEST RESULT FOR PERFORMANCE

|

| Component |

NSF 58 Performance Test |

Component |

Also Reduces/Rejects |

| Arsenic |

PASS |

Magnesium |

X |

| Barium |

PASS |

Calcium |

X |

| Chromium(+3) |

PASS |

Sodium |

X |

| Chromium(+6) |

PASS |

Nickel |

X |

| Cadmium |

PASS |

Mercury |

X |

| Copper |

PASS |

Zinc |

X |

| Cysts |

PASS |

Iron |

X |

| Fluoride |

PASS |

Ammonium |

X |

| Lead |

PASS |

Bicarbonate |

X |

| Radium (226/228) |

PASS |

Sulfate |

X |

| Selenium |

PASS |

Tannin |

X |

| Turbidity |

PASS |

Chloride |

X |

| TDS |

PASS |

Bromide |

X |

| Nitrate |

PASS |

Sediment |

X |

| Nutrite |

PASS |

|

|

|