Industrial RO Membrane4040, 440 Series |

1. OVERVIEW |

|

Rapid technological advancement brought about many benefits to our life and also concurrently caused pollution to our environments such as contaminating water sources from industry effluents.

Moreover, natural fresh water source could not meet the ever increasing water demand from our growing population and industries. Additionally, uneven seasonal rain fall makes the water shortage problem worse. Distillation has been traditionally used to obtain pure water from contaminated water sources. Other processes such as ion exchange and electrodialysis have been

Employed for water purification since 1950. |

|

Recently, RO membrane was applied to the desalination of sea water and brackish water. RO has been proven to be the most economical technology not only for the desalination of water containing salts, but also for pufiriying water contaminated with heavy metals, pesticides and other contaminants, and also RO can be used for recycling waste water and reclaiming useful materials from waste stream such as the recovery of dyes from dye industry effluents. The applications for RO also include food and beverage processing. In addition, advances in the fields of biotechnology and pharmaceuticals, coupled with advances in new membrane development, are making membranes and important separation step, which offers energy savings without leading to thermal degradation of the products. |

2. THEORY |

|

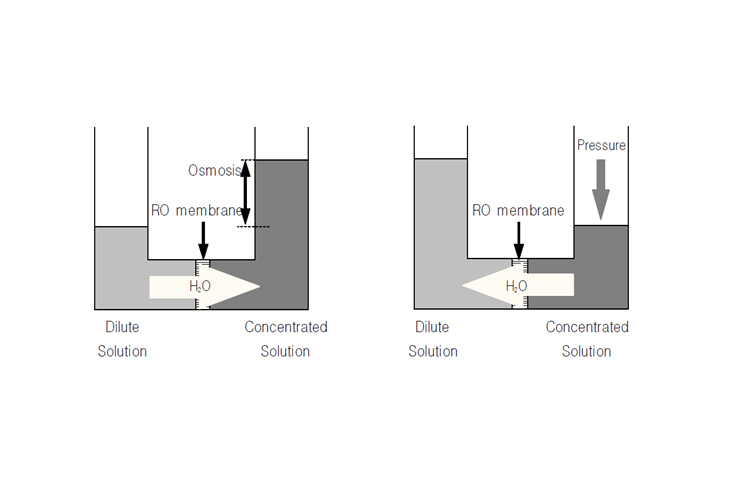

A semi-permeable membrane (RO membrane) is placed between two compartments. An RO membrane is consisted of a supporting layer with 50 is thickness and a barrier layer with about 0.2 in thickness. The phenomenon of osmosis occurs when pure water flow from a dilute saline solution in one compartment through the RO membrane into a higher concentrated saline solution in the other causing a rise in the height of the salt solution in the compartment of the higher concentrated solution. The water flow will stop when the pressure of the column of the salt solution equals to the difference in chemical potential between the two aqueous solutions. The equilibrium point of the water column height in terms of water pressure against the membrane is called osmotic pressure. If a force is applied to this column of water, the direction of water flow through the membrane can be reversed. This phenomenon is called reverse osmosis. This reversed flow produces pure water from the salt solution, since the membrane is not permeable to salt. |

|

3. CHARACTERISTIC PROPERTY OF WACO Corp RO MEMBRANES |

|

1) 2) 3) 4) 5) 6) 7) |

High permeate flux and high salt remection Chemically stable in a wide range of pH(pH 2~12) Long membrane life time Resistant to a biological attack Operable in a wide range of pressure (20~1000psig) Operable at a wide range of temperature (4~45) Economical |

* BRACKISH WATER USE |

| WACO Corp NanoH₂OTM brackish water RO membranes serve various municipal and industrial applications and have been operation in the major utilities around the world. Incorporating innovative Thin Film Nanocomposite (TFN) technology, all WACO Corp membranes provide superior performance along with intrinsic anti-fouling property and are suitable for applications where consistent and reliable performance is a must. |

| BW ES membranes offer high permeability at low feed pressure, significantly reducing operating costs: suitable for low to medium salinity brackish water applications. |  |

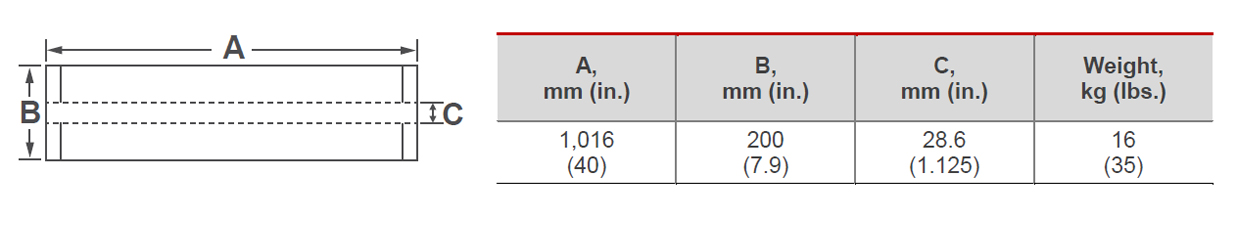

Product Specifications |

BW 4040 ES |

| Active Membrane Area, ft2(m2) | Permeate flow rate, GPD(m3/d) | Stabilized Salt Rejection, % | Minimum Salt Rejection, % | Feed Spacer, mil | Down |

| 85(7.9) | 2,500(9.5) | 99.5 | 99.2 | 28 | Show Detail PDF |

|

Test Conditions : 2000ppm NaCl at 25℃ (77℉), 150psi(10.3 bar), pH7, Recovery15% |

|

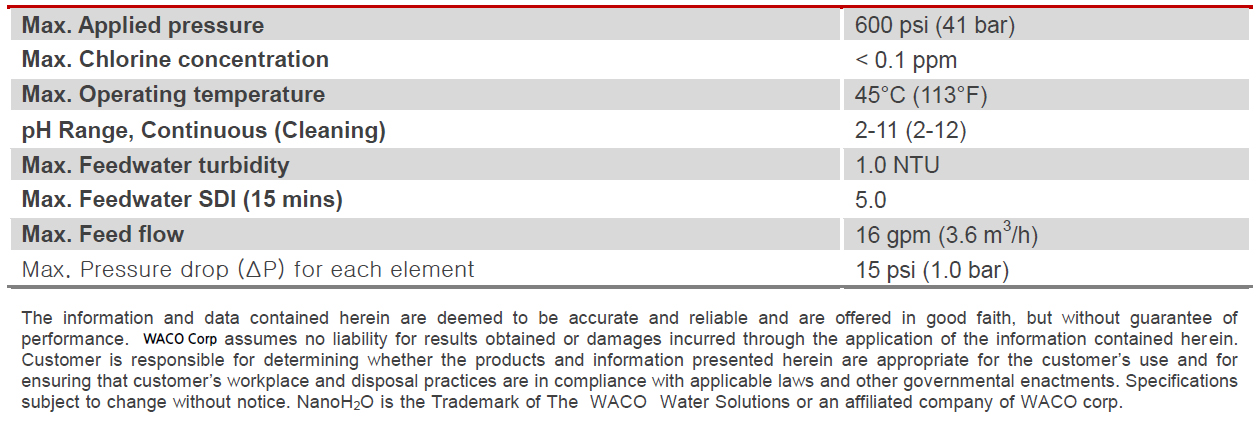

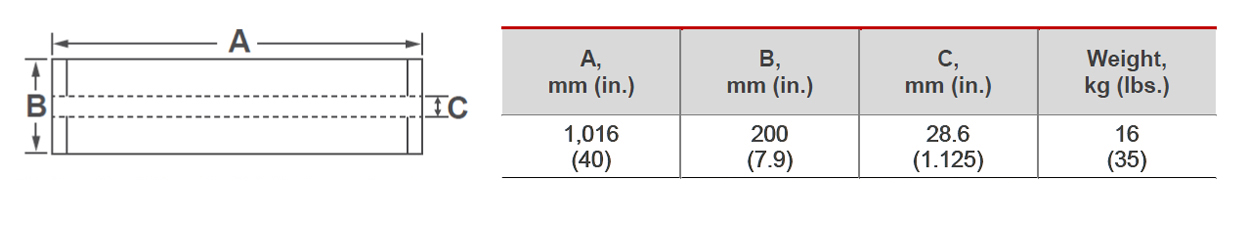

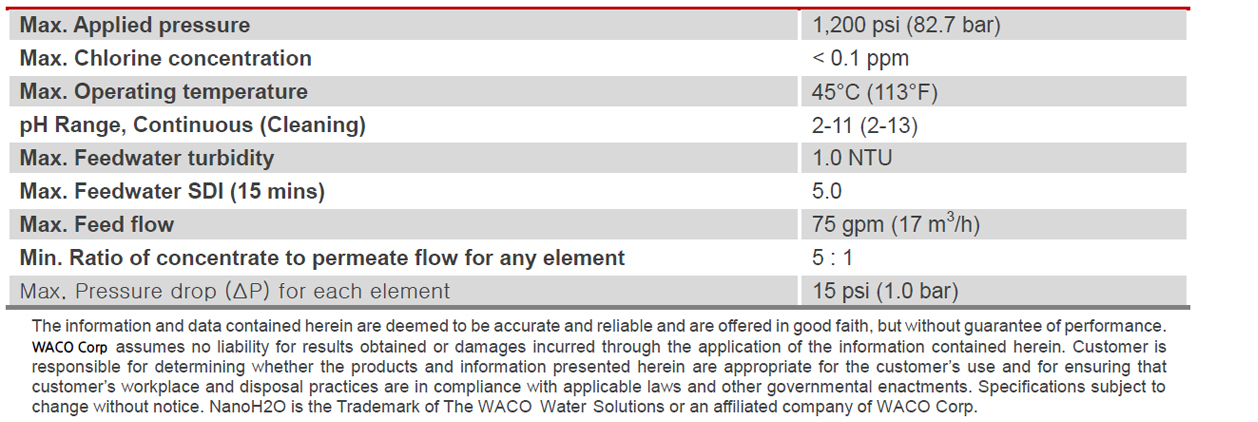

Operating Specifications |

|

BW 440 ES |

| Active Membrane Area, ft2(m2) | Permeate flow rate, GPD(m3/d) | Stabilized Salt Rejection, % | Minimum Salt Rejection, % | Feed Spacer, mil | Down |

| 440(41) | 11,550(43.7) | 99.6 | 99.5 | 28 | Show Detail PDF |

|

Test Conditions : 2000ppm NaCl at 25℃ (77℉), 150psi(10.3 bar), pH7, Recovery15% |

|

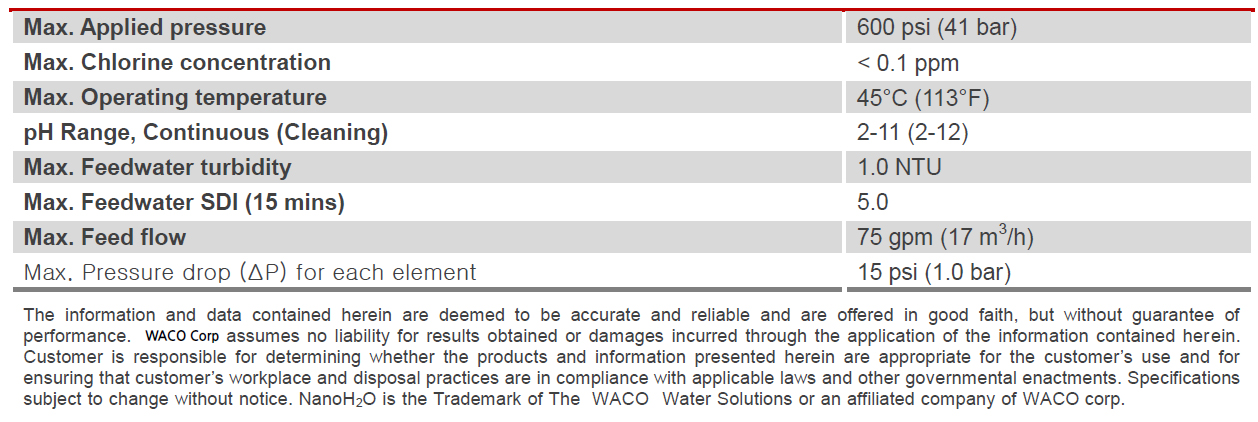

Operating Specifications |

|

* SEAWATER USE |

| WACO Corp NanoH₂OTM seawater RO membranes, incorporated with innovative Thin Film Nanocomposite (TFN) technology, reduce the cost of desalination while delivering superior water quality. Our seawater RO membranes provide industry leading salt rejection and produce 20% more flow than membranes manufactured with conventional technologies. We continue to leverage the thchnological advantages of our seawater RO membranes to expand our market share, accruing more than 3,000 Million Liter per Day(MLD) projects for both new and replacement market since the establishment. |

| SW ES(Energy Saving) membranes offer significant energy savings while producing good water quality, suitable for low to medium salinity seawater applications. |  |

Product Specifications |

SW 4040 R |

| Active Membrane Area, ft2(m2) | Permeate flow rate, GPD(m3/d) | Stabilized Salt Rejection, % | Minimum Salt Rejection, % | Feed Spacer, mil | Down |

| 80(7.4) | 1,950(7.4) | 99.7 | 99.5 | 28 | Show Detail PDF |

|

Test Conditions : 32,000ppm NaCl at 25℃ (77℉), 800psi(55 bar), pH8, Recovery8% |

|

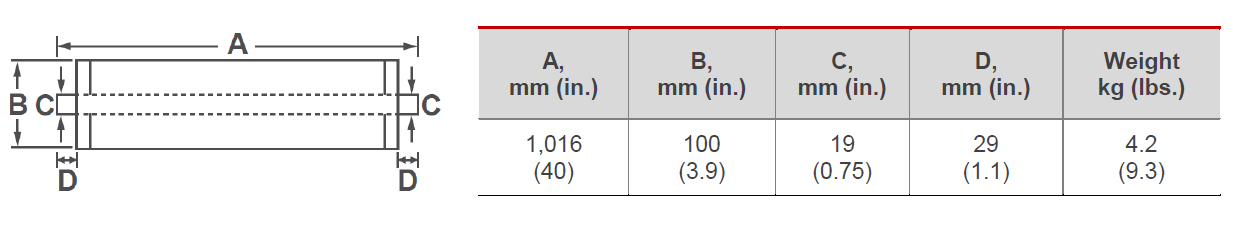

Operating Specifications |

|

SW 440 ES |

| Active Membrane Area, ft2(m2) | Permeate flow rate, GPD(m3/d) | Stabilized Salt Rejection, % | Minimum Salt Rejection, % | Boron Rejection, % | Feed Spacer, mil | Down |

| 440(41) | 15,070(57.5) | 99.8 | 99.6 | 89 | 28 | Show Detail PDF |

|

Test Conditions : 32,000ppm NaCl, 5ppm boron at 25℃ (77℉), 800psi(55 bar), pH8, Recovery8% |

|

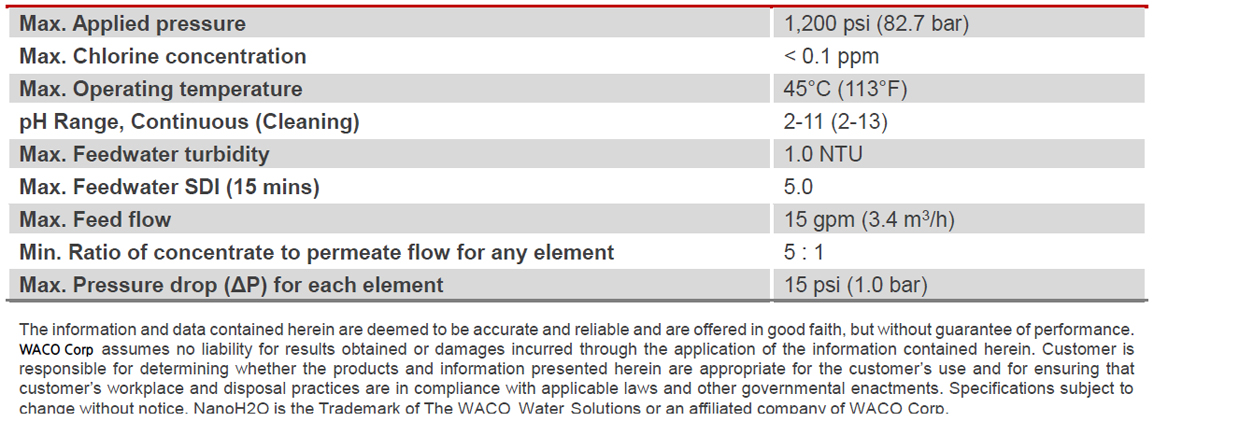

Operating Specifications |

|